new materials and new production processes

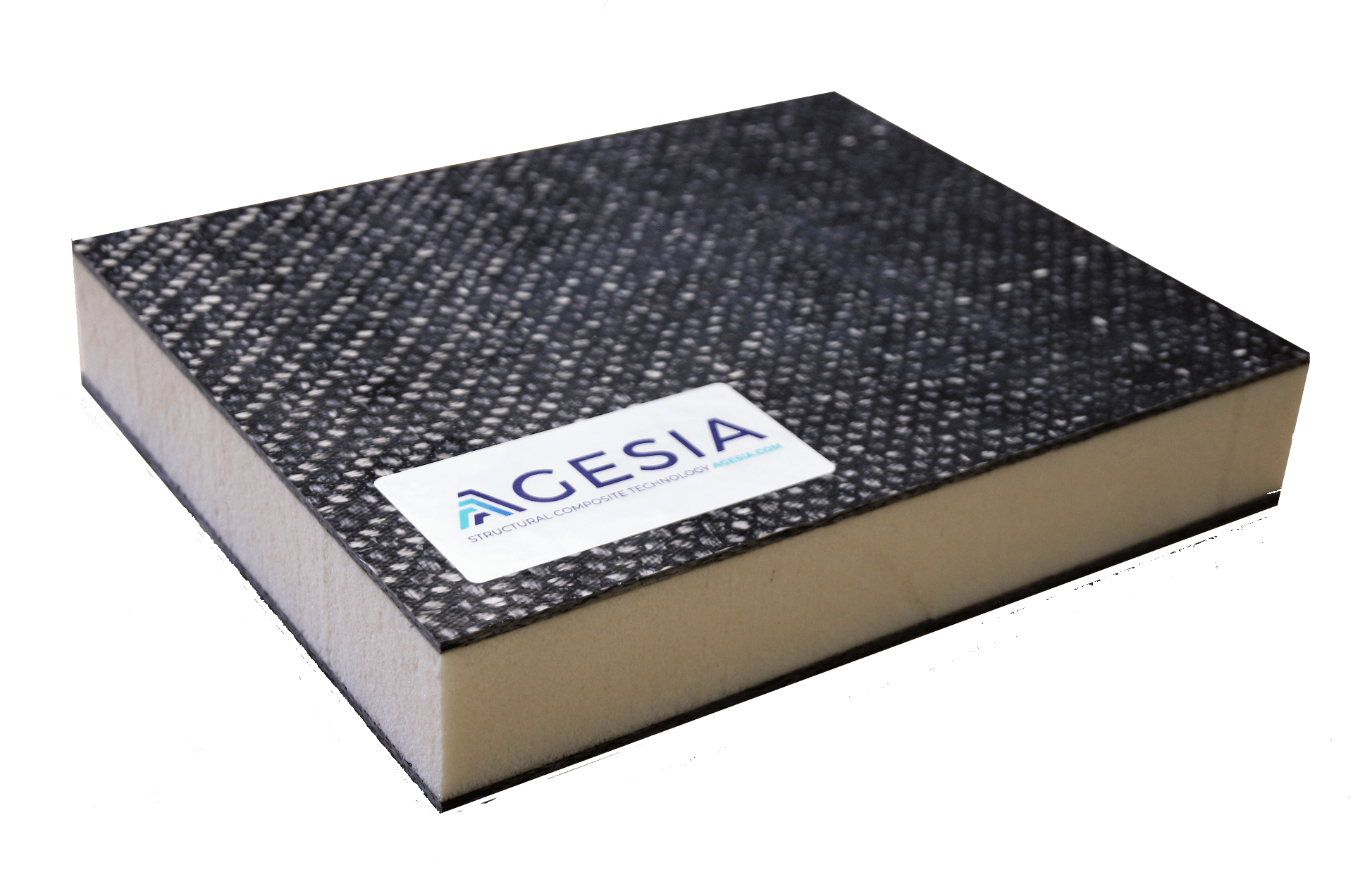

Development of a structural panel

- Toughest skin on the market

- Absolute skin-foam connection, no delamination

- Very high density foam, higher compression resistance

Based on 20 years of experience with thermoset sandwich panels, where the skins were stitched to the foam core so that they could not delaminate, a thermoplastic composite panel was developed, with revolutionary new and patented joining technology.

We develop each panel on behalf of a customer, tailored to the specific needs and properties to be achieved.

Order a sample!

Layers of a structural panel

FOAM

New Patented Joining Technology

Covalent Intermediate Bonding – CIB™

Agesia presents a revolutionary new method to connect two Thermoplastic composites and even Thermoplastic composites to metal.

This new invention, CIB™ (Covalent Intermediate Bonding) works on low pressure and low temperature and is capable of connecting vast surfaces.

This method is the base of the development of our strong sandwich panels.

Covalent Bond

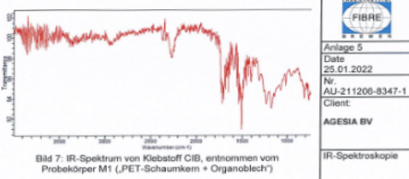

Faserinstitut Bremen, specialized in tests at the molecule level, states in its test report (AU-211206-8347-1-B1) that CIB™, using IR-Spektroskopie, can no longer be found in the PET-foam or PA-6 matrix. This means there is a covalent chemical bond.

This document and the information therein are the property of Agesia bv and may only be used for the purpose for which it is supplied. Reproduction of use of the information therein, in whole or in part, is strictly prohibited without written permission of Agesia bv.